The Astm Standard Inserts are made from high-quality raw materials, resulting in high-quality Astm Standard Insert. The components included in Astm Standard Insert' chemical makeup provide them with the appropriate traits and attributes. As a result, these Astm Standard Inserts work admirably.

The Astm 304 Standard Inserts are created with the appropriate laws and regulations in mind, ensuring that the client's needs and expectations are met. They are created while also taking into account the necessary rules, norms, and standards in order to produce high quality Astm 316 Standard Insert. Therefore, these are used in a large range of industrial applications.

Largest Inventory

Customer Support

On Time Deliveries

ISO 9001 : 2015

Specification :-

| Standard | DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

| Specification | DIN 931, DIN 933, DIN 912, ASTM A-193, ASTM A-194, ASTM A325, ASTM A320, ISO ( 4762, 4017, 4014) and all International Standards |

| Inserts Size | M2 to M160, as per required |

| Length | 3 mm to 1000 mm, as per required |

| Bolts Threads: | METRIC, BSW, BSF, UNC, UNF or as per required |

| Coating | Plain / Zinc plated / HDG 6az / Teflon / PTFE / Zinc aluminum flake / Geomet |

| Test Certificate: | Manufacturer Test Certificate as per EN 10204 / 3.1 |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| B8 (AISI 304) | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| B8M (AISI 316) | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| B8 CL2(AISI 304) | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| B8C(AISI 347) | 1.4550 | S34700 | SUS 347 | - | - | - | X6CrNiNb18-10 |

| B6(AISI 410) | 1.4006 | S41000 | SUS 410 | 410S21 | - | - | X12Cr13 |

| B6X(AISI 410) | 1.4006 | S41000 | SUS 410 | 410S21 | - | - | X12Cr13 |

| B8T(AISI 321) | 1.4541 | S32100 | SUS 321 | - | - | - | X6CrNiTi18-10 |

| B8MLCuN(AISI 304) | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| Grade 8 (AISI 304) | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| Grade 8M (AISI 316) | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| Grade 8C(AISI 347) | 1.4550 | S34700 | SUS 347 | - | - | - | X6CrNiNb18-10 |

| Grade 6(AISI 410) | 1.4006 | S41000 | SUS 410 | 410S21 | - | - | X12Cr13 |

| Grade 6X(AISI 410) | 1.4006 | S41000 | SUS 410 | 410S21 | - | - | X12Cr13 |

| Grade 8T(AISI 321) | 1.4541 | S32100 | SUS 321 | - | - | - | X6CrNiTi18-10 |

| Grade 8MLCuN(AISI 304N) | 2.4856 | N06304n | - | 3076 | - | - | - |

| 1.4980 | 1.4980 | S66286 | - | - | - | - | - |

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| B8 (AISI 304) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 18.00 - 20.00 | - | 8.00 - 11.00 | - |

| B8M (AISI 316) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 16.0 – 18.0 | 2.00 – 3.0 | 10.0 – 14.0 | - |

| B8 CL2 (AISI 316) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 16.0 – 18.0 | 2.00 – 3.0 | 10.0 – 14.0 | - |

| B8C (AISI 347) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 17.00 - 19.00 | - | 12.00 - 13.00 | - |

| B6 (AISI 410) | 0.08 - 0.15 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 11.5 - 13.5 | - | - | - |

| B6X (AISI 410) | 0.08 - 0.15 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 11.5 - 13.5 | - | - | - |

| B8T (AISI 321) | 0.10 min | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 4.00-6.00 | 0.40-0.65 | - | - |

| B8MLCuN (AISI 304) | 0.02 max | 1.00 max | 0.80 max | 0.030 max | 0.010 max | 19.50 - 20.50 | 6.00 - 6.50 | 17.50 - 18.50 | - |

| Grade 8 (AISI 304) | 0.080 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 18.0-20.0 | - | 8.0-11.0 | - |

| Grade 8M (AISI 316) | 0.080 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 16.0-18.0 | 2.00-3.00 | 10.0-14.0 | - |

| Grade 8C (AISI 347) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 17.00 - 19.00 | - | 12.00 - 13.00 | - |

| Grade 6 (AISI 410) | 0.08 - 0.15 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 11.5 - 13.5 | - | - | - |

| Grade 6X (AISI 410) | 0.08 - 0.15 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 11.5 - 13.5 | - | - | - |

| Grade 8T (AISI 321) | 0.10 min | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 4.00-6.00 | 0.40-0.65 | - | - |

| Grade 8MLCuN (AISI 304) | 0.02 max | 1.00 max | 0.80 max | 0.030 max | 0.010 max | 19.50 - 20.50 | 6.00 - 6.50 | 17.50 - 18.50 | 0.18 - 0.22 |

| 1.4980 | 0.08 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 13.5-16.0 | 1.00-1.50 | 24.0-27.0 | - |

Applications & Operations

We at DC Engineering make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers. DC Engineering is one of the most trusted manufacturers and suppliers of fasteners and bolts which are applicable in various industries.

- Gas Processing Industries

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Chemical Industries

- Oil & Gas Industries

- Fertilizers Industries

- Sugar Industries

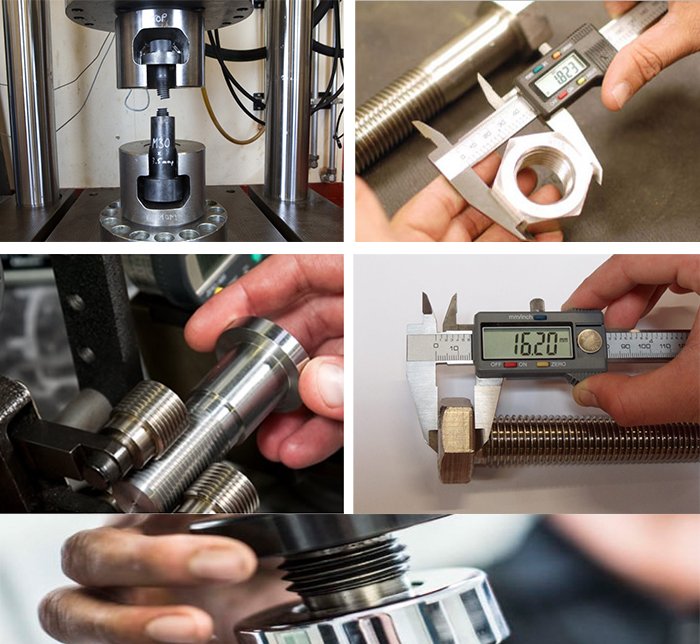

Experimentation & Testing

DC Engineering is known for its accurate and perfect dimensions. We at DC engineering thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Impact Analysis

- Eddy Current Examining

- Power Generation Industries

- Hydrostatic Analysis

- Prompt Test

- Positive Material Recognition

- Large-Scale Test

- Pitting Protection Test

Packaging & Dispatching

DC Engineering uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Crates

- Wooden Pallets

- Carton Boxes

- Shrink-Wrapped

- Bubble Wrap Packing Material

- Laminated & Metallized Films

- Wooden or Plastic Crates

Cities We Export

Srinagar, Tamil Nadu, West Bengal, Vijayawada, Maharashtra, Rajkot, Karnataka, Akola, Amravati, Kanpur, Aurangabad, Andhra Pradesh, Saharanpur, Vasai, Varanasi, Faridabad, Bhadreswar, Jhansi, Nashik, Solapur, Surat, Nagpur, Raipur, Haryana, Buxar, Bhavnagar, Pune, Punjab, Banswara, Uttar Pradesh, Tadepalligudem, Manipur,Delhi, Dhanbad, Guntur, Gujarat, Ludhiana, Kalyani, Nagapattinam, Benin, Vadodara, Kerala, Patna, Ulhasnagar, Chhattisgarh, Mizoram, Chennai, Kurnool, Datia, Mangalore, Ambala, Kota, Miryalaguda, Orissa, Mumbai, Nagda, Bikaner, Ballia, Allahabad, Suryapet, Jaipur, Haora, Durgapur, Udgir, Jodhpur, Amritsar, Kalyan, Bangalore, Puducherry, Agra, Kolkata, Tirunelveli, Gujarat, India, Lucknow, Meerut, Dehradun, Bihar, Ujjain, Jharkhand, Ahmedabad, Coimbatore, Sadar, Jamnagar, Hyderabad, Chandigarh, Ranchi, Jamalpur, Ambattur, Jabalpur, Waghala, Nagaur, Gulbarga

Countries We Export

Iran, Ecuador, Mexico, Afghanistan, Bulgaria, Denmark, Kenya, Singapore, Portugal, Venezuela, Sri Lanka, Chile, Gabon, Colombia, Belgium, Peru, Belarus, Yemen, Thailand,France, Italy, Mexico, Greece, Kuwait, Romania, Iraq, Netherlands, Sweden, Switzerland, Lithuania, Lebanon, Poland, Philippines, United Kingdom, Norway, Angola, Kazakhstan, Taiwan, Nigeria, Poland, China, Nigeria, Spain, Mongolia, New Zealand, United States, Hungary, Libya, Serbia, Ukraine, Finland, South Africa, Iran, Vietnam, Israel, Czech Republic, Slovakia, Hong Kong, Azerbaijan, Qatar, Japan, Oman, Malaysia, Pakistan, Algeria, Bangladesh, Jordan, Indonesia, Russia, United Arab Emirates, Brazil, Estonia, Turkey, Austria, Croatia, Ghana, Bahrain, Korea, Canada, Bolivia, Costa Rica, Trinidad & Tobago, Tunisia, Chile, Morocco, Bhutan, Argentina, Egypt