These fasteners are available in various shapes, sizes, and physical and mechanical characteristics, making them different from the other fasteners. Inconel 600/601/625 Fasteners are also available in multiple customer-required specifications to suit diverse needs. They are made up of a combination of different types of materials. Inconel 600 alloy is used where people require corrosion-resistant materials as it is an alloy of chromium and nickel.

These fasteners can also be used at temperatures above 2200 degrees Fahrenheit, and thus these can withstand oxidation at even the highest temperatures. The ASTM B166 Inconel 601 Fasteners can also withstand high temperatures and is very malleable, which makes its life long. As it has high oxidation resistance that is less likely to get rusted, it is also used in various applications. Inconel 625 is an alloy that is made by combining chromium, nickel, and molybdenum. As these fasteners are also made up of chromium and nickel, they are also resistant to oxidation at higher temperatures.

The addition of aluminum is also used at times to this alloy to make it more perfect. These are also mechanically very strong and can withstand various chemical environments, which could erode them. Hence, because of its properties and characteristics, UNS N06625 Fastener is used in a wide range of applications, ranging from oil to paper and pulp industries. Various types of tests are also done on these fasteners to provide these fasteners to the customers in a better shape and quality.

Largest Inventory

Customer Support

On Time Deliveries

ISO 9001 : 2015

Specification

| Specifications | ASTM B166 ASME SB166 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM |

| Size | M0.2 to M33 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Packing | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating |

Cadmium Coating Hot Dipped Galvanizing Coating Ptfe Coated Nickel Alloy 200 Fasteners Phosphate Coating Teflon Coating Xylon Coating Zinc Coating |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al-Ti |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 | - |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Bal | 58.0 -63.0 | 21.0 – 25.0 | - |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 – 23.0 | 0.40 max |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600/601 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Applications & Operations

We at DC Engineering make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers. DC Engineering is one of the most trusted manufacturers and suppliers of fasteners and bolts which are applicable in various industries.

- Gas Processing Industries

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Chemical Industries

- Oil & Gas Industries

- Fertilizers Industries

- Sugar Industries

Experimentation & Testing

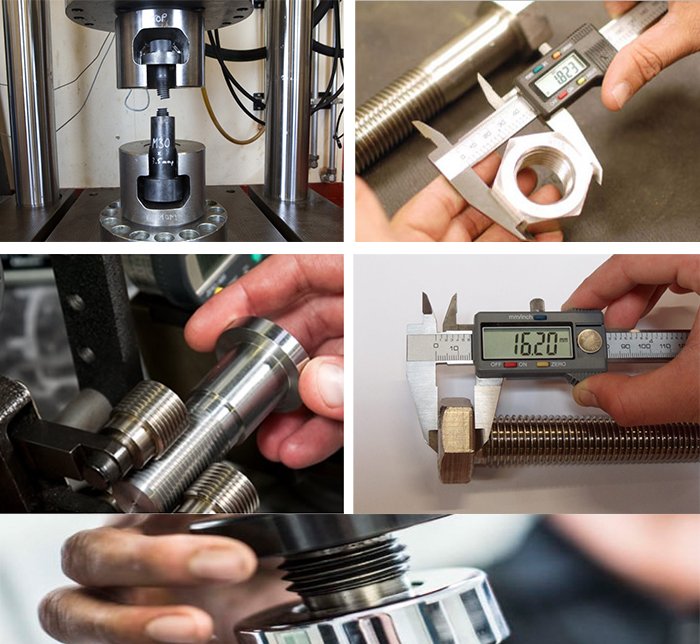

DC Engineering is known for its accurate and perfect dimensions. We at DC engineering thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Impact Analysis

- Eddy Current Examining

- Power Generation Industries

- Hydrostatic Analysis

- Prompt Test

- Positive Material Recognition

- Large-Scale Test

- Pitting Protection Test

Packaging & Dispatching

DC Engineering uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Crates

- Wooden Pallets

- Carton Boxes

- Shrink-Wrapped

- Bubble Wrap Packing Material

- Laminated & Metallized Films

- Wooden or Plastic Crates

Cities We Export

Srinagar, Tamil Nadu, West Bengal, Vijayawada, Maharashtra, Rajkot, Karnataka, Akola, Amravati, Kanpur, Aurangabad, Andhra Pradesh, Saharanpur, Vasai, Varanasi, Faridabad, Bhadreswar, Jhansi, Nashik, Solapur, Surat, Nagpur, Raipur, Haryana, Buxar, Bhavnagar, Pune, Punjab, Banswara, Uttar Pradesh, Tadepalligudem, Manipur,Delhi, Dhanbad, Guntur, Gujarat, Ludhiana, Kalyani, Nagapattinam, Benin, Vadodara, Kerala, Patna, Ulhasnagar, Chhattisgarh, Mizoram, Chennai, Kurnool, Datia, Mangalore, Ambala, Kota, Miryalaguda, Orissa, Mumbai, Nagda, Bikaner, Ballia, Allahabad, Suryapet, Jaipur, Haora, Durgapur, Udgir, Jodhpur, Amritsar, Kalyan, Bangalore, Puducherry, Agra, Kolkata, Tirunelveli, Gujarat, India, Lucknow, Meerut, Dehradun, Bihar, Ujjain, Jharkhand, Ahmedabad, Coimbatore, Sadar, Jamnagar, Hyderabad, Chandigarh, Ranchi, Jamalpur, Ambattur, Jabalpur, Waghala, Nagaur, Gulbarga

Countries We Export

Iran, Ecuador, Mexico, Afghanistan, Bulgaria, Denmark, Kenya, Singapore, Portugal, Venezuela, Sri Lanka, Chile, Gabon, Colombia, Belgium, Peru, Belarus, Yemen, Thailand,France, Italy, Mexico, Greece, Kuwait, Romania, Iraq, Netherlands, Sweden, Switzerland, Lithuania, Lebanon, Poland, Philippines, United Kingdom, Norway, Angola, Kazakhstan, Taiwan, Nigeria, Poland, China, Nigeria, Spain, Mongolia, New Zealand, United States, Hungary, Libya, Serbia, Ukraine, Finland, South Africa, Iran, Vietnam, Israel, Czech Republic, Slovakia, Hong Kong, Azerbaijan, Qatar, Japan, Oman, Malaysia, Pakistan, Algeria, Bangladesh, Jordan, Indonesia, Russia, United Arab Emirates, Brazil, Estonia, Turkey, Austria, Croatia, Ghana, Bahrain, Korea, Canada, Bolivia, Costa Rica, Trinidad & Tobago, Tunisia, Chile, Morocco, Bhutan, Argentina, Egypt

Popular Searches

ASME SB446 industrial Fastener manufacturer in Indonesia, ASME SB446 high tensile Fastener dealer in Thailand, ASME SB446 industrial Fastener trader in Chennai, ASME SB446 industrial Fastener trader in Ahmedabad, Inconel 625 high tensile Fastener stockiest in Philippines, UNS N06600 Hot Forged Fastener trader in Vietnam, ASTM B166 Hot Forged Fastener dealer in Pune, ASTM B166 Hot Forged Fastener trader in Pune, Inconel 600 industrial Fastener wholesaler in Chennai, UNS N06600 high tensile Fastener stockiest in Sharjah, UNS N06601 industrial Fastener retailer in Kolkata, Grade Inconel 601 industrial Fastener retailer in Thailand, ASTM B166 high tensile Fastener stockyards in Oman, ASTM B166 high tensile Fastener dealer in Sharjah, ASME SB166 industrial Fastener stockyards in Kolkata.